Steady Power. Zero Vibration.

With German hydraulic patents & IP68 rating. Resists 85dB bass, holds 600W devices steady. CE certified. Professional anti-shake for kitchens.

Resonance Pain Point Solution

Pain Point scene | Fatal risk | Microstepping solutions |

The heavy bass caused the shaking | Equipment dumping/liquid sputtering | Three-stage hydraulic damping system (amplitude < 0.5 mm) |

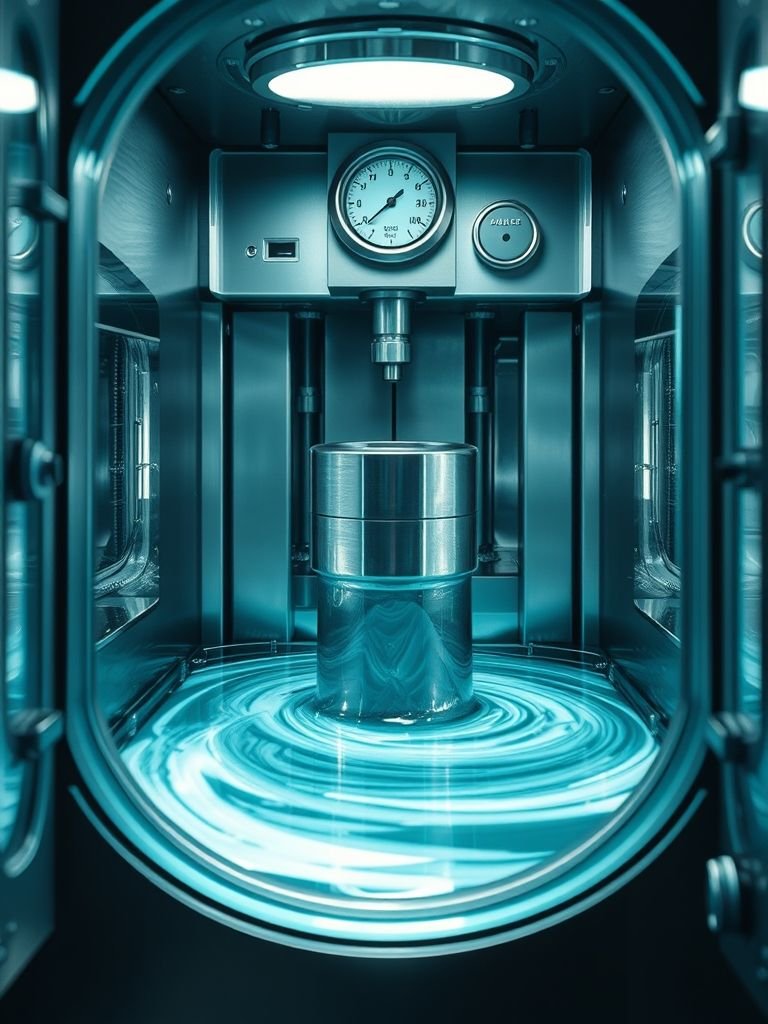

The Lampblack invades the mechanical structure | The lifting mechanism is jammed | Hermetically sealed stainless steel protective chamber |

Wear and tear in high frequency service | Abnormal rise and fall occurred in half a year | 300,000 lifetime tests (industry standard) |

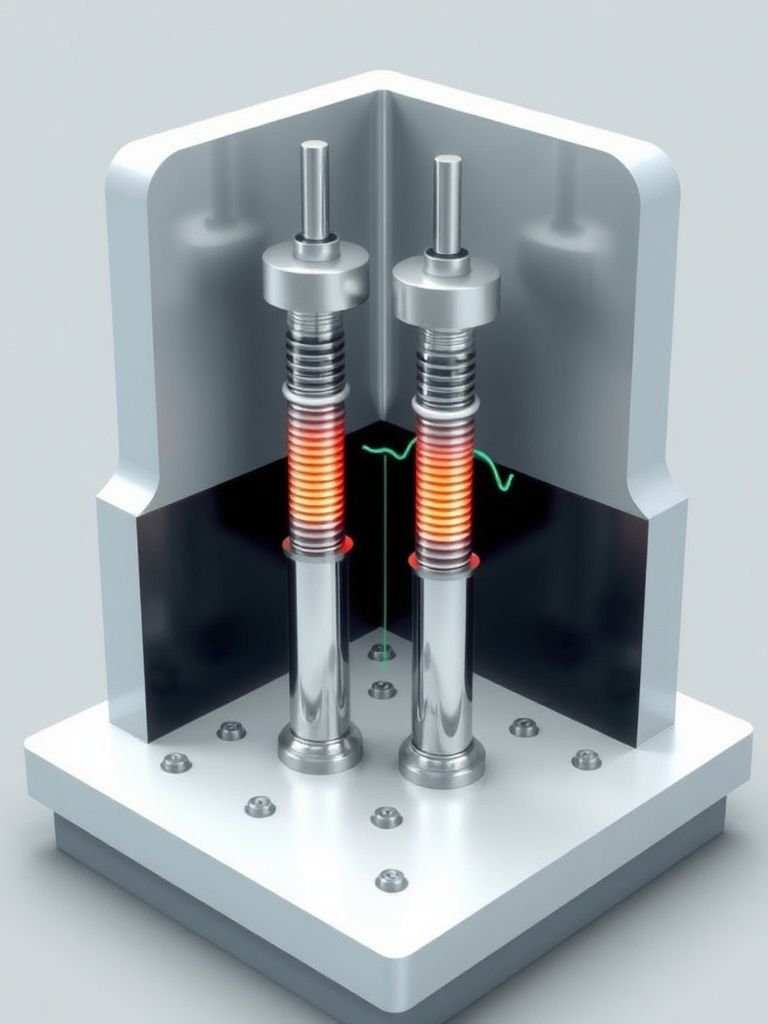

Demonstration Of Three Core Technologies

StableLift™ Anti-vibration lifting and lowering

Tech highlights:

Amplitude control: < 0.5 mm (85dB environment)

Load-bearing capacity: 15 kg equipment full load operation

AquaShield Pro waterproof system

Authentication parameters:

IP68 protection level (1M/1H)

Nano self-cleaning coating (oil contact angle > 110 °)

MODUCONNECTTM module system

Functional advantages:

3 second hot swap replacement

Intelligent power allocation (200-600W adaptive)

The Case Of European Island Platform

![raphael-ai(10) {"prompt":"Amidst the bustling atmosphere of a Michelin-starred kitchen, chefs clad in crisp white uniforms perform a hypnotic dance of culinary artistry, their focused movements seamlessly blending in a flurry of precision and finesse. The warm, inviting glow of overhead lights bathes the kitchen in a golden hue, illuminating polished stainless steel countertops and vibrant ingredients laid meticulously in preparation. In the background, a stylish DJ booth pulses with rhythmic energy, decorated with colorful LED lights that sync to the upbeat music energizing the space. This lively fusion of gastronomy and rhythm creates an electrifying ambiance, celebrating both the craft of cooking and the art of music, where the scent of gourmet dishes mingles with a tantalizing soundscape of deep bass and uplifting melodies.nn"Michelin kitchen during live cooking with DJ booth visible in background","originalPrompt":""Michelin kitchen during live cooking with DJ booth visible in background","width":1024,"height":1024,"seed":42,"model":"flux","enhance":false,"nologo":true,"negative_prompt":"worst quality, blurry","nofeed":false,"safe":false,"quality":"medium","image":[],"transparent":false,"isMature":false,"isChild":false}](https://wayboosocket.com/wp-content/uploads/elementor/thumbs/raphael-ai10-r8w6dqke7n0kp8fbzn3e0df8yrw32sw4gi9t1qa84g.jpeg)

Chef testimony

“Our espresso machines are rock solid even with heavy metal music!”

Chef Müller, Sterne Berlin

The Challenge

– open kitchen with live DJ Performance

– coffee machine dumping accident due to equipment resonance

The solution

1. Integrated 6 groups of anti-vibration lifting modules on the island

2. Custom Euro/USB-C Hybrid Jack

3. Safety guidelines for night-time breathing lamps

Outcomes

✓ vibration accident to Zero

✓ equipment maintenance cost ↓68%

Process Of Kitchen Project

01.

Testing of vibration environment

A professional acoustic scanner captures 20-200 Hz vibration sources to generate a kitchen resonance thermogram.

02.

3D resonance simulation

Ansys mechanical simulation previews the amplitude of the equipment under 85 db sound pressure, and the error rate is less than 3% .

03.

Customization of Vibration Reduction Scheme

According to the data matching German hydraulic damping module, single-point load-bearing scheme to 0.1 kg.

04.

Assembly of components in Germany

Munich precision workshop integrated Festo pneumatic system, 0.01 mm error control.

05.

Laser leveling on site

The laser positioner calibrates the lift axis to ensure ± 0.2 mm horizontal accuracy.

06.

Life-long vibration monitoring

The IoT sensor sends back the amplitude data in real time, and the abnormal vibration automatically alarms.

Performance Pledge:48-hour response to maintenance,Free upgrade of vibration sensor。

- Step 1:Type of kitchen

- Step 2: Critical equipment

- Step 3: Operational environment